ISO CE Motorized Heavy Duty Smoothly Running Crane End Beam

Overview European standard crane end beamGeneral standard crane end beam General standard crane end beam Crane End Beam ;

- Overview

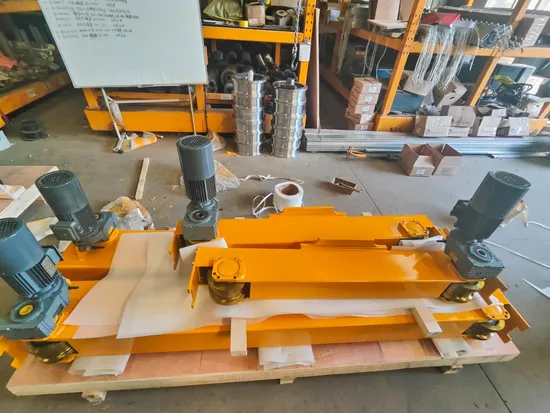

- Product Description

- Detailed Photos

- Product Parameters

- Main components

- Company Profile

Basic Info.

| Model NO. | MATE-EB |

| Certification | RoHS, CE, ISO9001 |

| Condition | New |

| Operation Form | Remote Control |

| Maximum Lifting Height | 25-30m |

| Maximum Lifting Weight | 50-100t |

| Main Girder Form | Single Girder |

| Type | Ordinary |

| Product Name | Crane End Beam |

| Application | for Single Double Beam Crane |

| Lifting Capacity | 1-200 Tons |

| Control Method | Wireless Remote Control |

| Running Speed | 0-20 M/Min |

| Power Supply | 380V 220V 200V 50Hz |

| Transport Package | Standard Packaging/ Export Wooden Box |

| Specification | Customized size |

| Trademark | CATET |

| Origin | Henan China |

| HS Code | 8426 |

| Production Capacity | 5000 Sets/ Year |

Product Description

European standard crane end beamGeneral standard crane end beam General standard crane end beam

Crane End Beam

Crane end carriages play a crucial role in supporting and guiding the movement of overhead cranes along the runway beams. They are essential components that help distribute the weight of the crane and its load, ensuring smooth and controlled operation.Our end carriages are compact, rail-mounted travel units for direct connection to crane girders and other load-bearing structures.

The end carriages consist of a torsionally rigid box section, wheel blocks and one of our geared motors. They offer excellent travel characteristics - also for high loads. Their strengths in detail:

• optimum travel characteristics

• smooth starting thanks to matching drive solutions

• high operating reliability

• easy assembly and accessibility

• for single and double-girder overhead travelling cranes, suspension cranes and travelling structures.

Box beam

Drive Mechanism / The operating mechanism adopts a three-in-one drive system of motor, reducer, and brake to achieve three-in-one drive and improve the safety and reliability of the equipment. /The motor adopts a three-phase AC variable frequency motor. /The reducer adopts a hard tooth surface reducer. /The brake uses electromagnetic brake. Asbestos-free brake pads and brake discs are used.

Wheel Part

Product Description Detailed Photos

Product Parameters

| Number | Item | Parameters |

| 1 | Crane type | Single Double beam overhead gantry crane |

| 2 | Lifting capacity | 1-200 tons |

| 3 | Lifting height | 1-31m |

| 4 | Control method | Wireless remote control/ Cab control |

| 5 | Working level | A4-A7 |

| 6 | Running speed | 0-20 m/min |

| 7 | Power supply | 3p 4p 220v 360v 50hz |

| 8 | Protection class | IP54 |

Cross-sectional shape: "square box" shape is adopted. This structure has high rigidity and good bending resistance. Material selection: usually made of high-strength steel plates to ensure sufficient mechanical strength. Common materials include Q345B, Q235B, etc. Welding process: each component of the square box beam is welded with high quality to ensure the integrity and reliability of the beam. Strengthening design: adding reinforcement ribs at key locations to improve the torsional and bending resistance of the beam. -The wheel is made of 40Cr or 42CrMo alloy steel, which is tempered as a whole, with high hardness, wear resistance,and long life. -It has the characteristics of high hardness, strong load-bearing capacity, wear resistance, and long life. -The bearing uses self-aligning bearing. -Adopts angle round box and buffer device. -Modular design to meet the needs of various customers.

Company Profile

You may also like

Send inquiry

Send now